Barista Hustle has had a love-hate relationship with nutation through the years. Chances are you’ll recall such classics as “Nutation: an Apology’. While it’s an enchanting distribution methodology, we’ve by no means managed to reign it in in a approach that may be practicable behind the bar. Not for need of attempting: A few years again, within the lead as much as the AutoComb mission, we had one other take a look at nutation and went so far as constructing a nutation equipment. It’s no cakewalk making a tamping machine the place the piston presses downward whereas concurrently swivelling in a decent, decaying spiral — like a 20-cent coin wobbling on the finish of a spin — gently redistributing grounds throughout the puck surface.

The appliance was a non-starter, not because it didn’t work. Actually it was excellent at nutating, but it made the puck so dense that it required a super coarse grind that always underextracted. More recently, our thoughts have returned there, particularly after Lance Hedrick and Mark Al-Shemmeri started talking about densification. I mean, the theory of densification is pretty great: You can grind up a coffee bean, then squish all the fines back into the boulders. And during the squishing process, there’s the other possible benefit of rounding off the edges of the boulders. By the end of an ideal densification process, you end up with what looks like a delightful little box of microscopic marbles, all of equal size and shape, just waiting for water to slide between the perfectly equal spacing between each particle. What a dream.

Annoyingly, massive industry gets to make good use of densifiers for things like capsule coffee. Some (not all) capsule companies do amazing things with very small amounts of coffee squeezed into very small spaces. Of course there are plenty of companies selling capsules using white label roasters who grind the coffee on EK43s and do little more than drop the grinds into the capsule, gas them with nitrogen and then whack a foil sticker on the top. But some companies use densifiers like this bad boy (below) which, just like Roller Mills, are brilliant at processing 400 pounds of coffee per hour and thus, are never used by those who would appreciate them the most — baristas.

This is the ‘mini densifier’ from MPE — designed to do up to 400lb/h of ground coffee! If 400 pounds is the output from the ‘mini’, can you imagine what the big dog can manage?!

This is the ‘mini densifier’ from MPE — designed to do up to 400lb/h of ground coffee! If 400 pounds is the output from the ‘mini’, can you imagine what the big dog can manage?!

Here’s how a densifier works: ‘Special angled paddles are used to apply compressive force to the coffee. An adjustable discharge gate determines the magnitude of compressive force applied before coffee is expelled through the discharge.’

After reading the words ‘special angled paddles’ and ‘compressive forces’, it doesn’t half sound like nutation — right? So our thoughts tended back to our nutation machine once again, and how we might design an experiment to find out if nutation of coffee grinds leads to the densification of individual coffee grinds. If that were the case, then a table top densifier would be well worth the expense. Here’s what we came up with as an experiment:

The Nutation and Sieving Experiment

Unfortunately, parts from our nutation machine were scavenged by our R&D department for early AutoComb prototyping. So, in designing a test to find out if nutation can do densification, we knew we’d need to do manual nutation, and a lot of it to match the nutating power of the mechanical nutator. We did two grueling minutes of spinning the tamper around whilst applying downwards force for five replicates of each sample we tested.

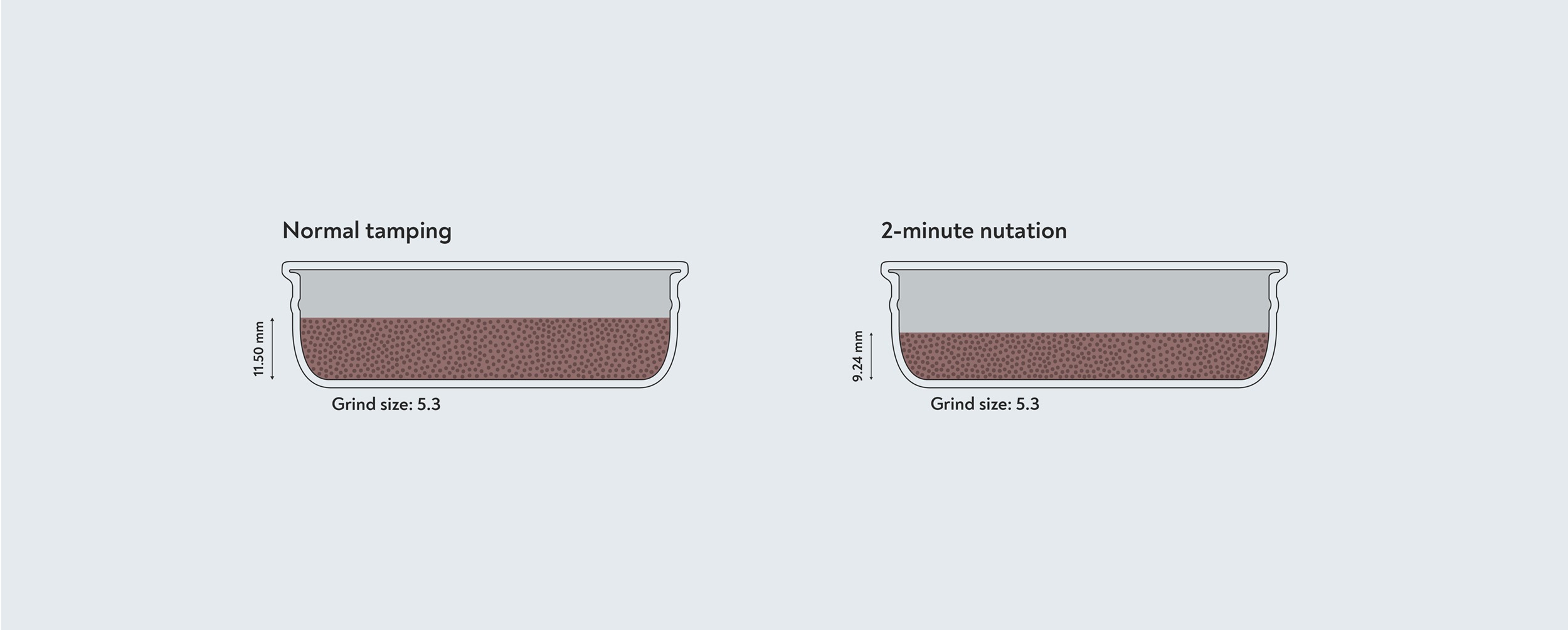

The first jaw dropping discovery about heavy nutation was that it increases the bulk density of the tamped coffee bed by 25%!!!

As you can see above, normal tamping achieved a bed depth of 11.5 mm, whereas two solid minutes of nutation achieved a bed depth of 9.24 mm. That’s only a difference of 2.26 millimeters of bed depth, but it represents a massive change in the density of the puck. Here are the calculated bulk densities based on our puck depth data:

- Normal grinds: ~0.582 g/cm³

- Nutated grinds: ~0.725 g/cm³

It confirms significant ‘macro’ densification — the nutated grinds are packing more tightly, likely due to better particle rearrangement and reduced void spaces. This densification explains why you might observe similar or longer shot times at coarser grind settings in nutated pucks. But what we really want is ‘micro’ densification or changing the effective shape of individual particles.

What Does Nutation Do to Boulders?

We hypothesised that during nutation, coffee grinds would act upon each other like little pieces of sand paper and have the effect of rubbing off angular pieces of grinds, slowly making them more spherical. For want of an electron microscope to test this, we grabbed the 355-µm sieve.

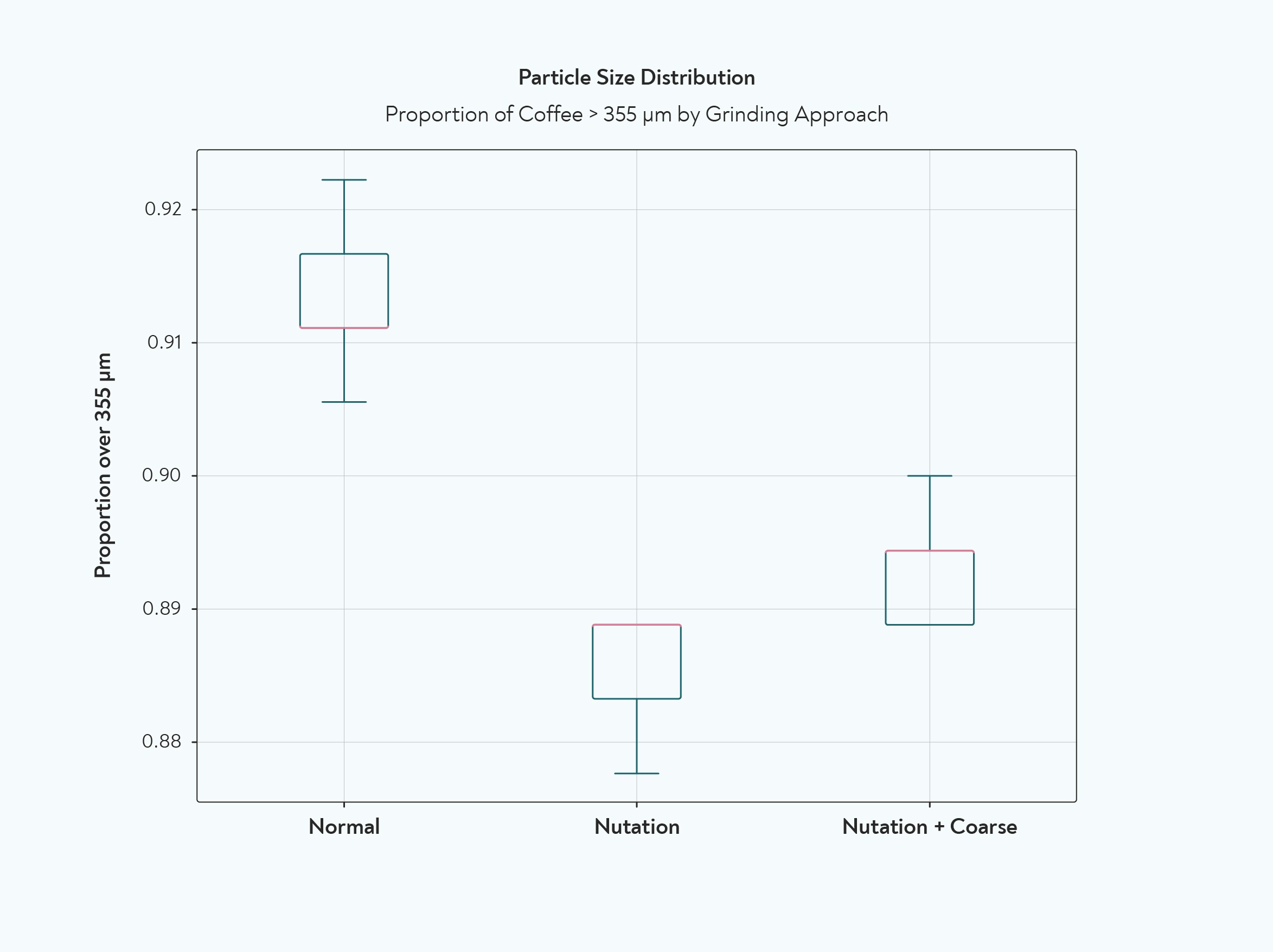

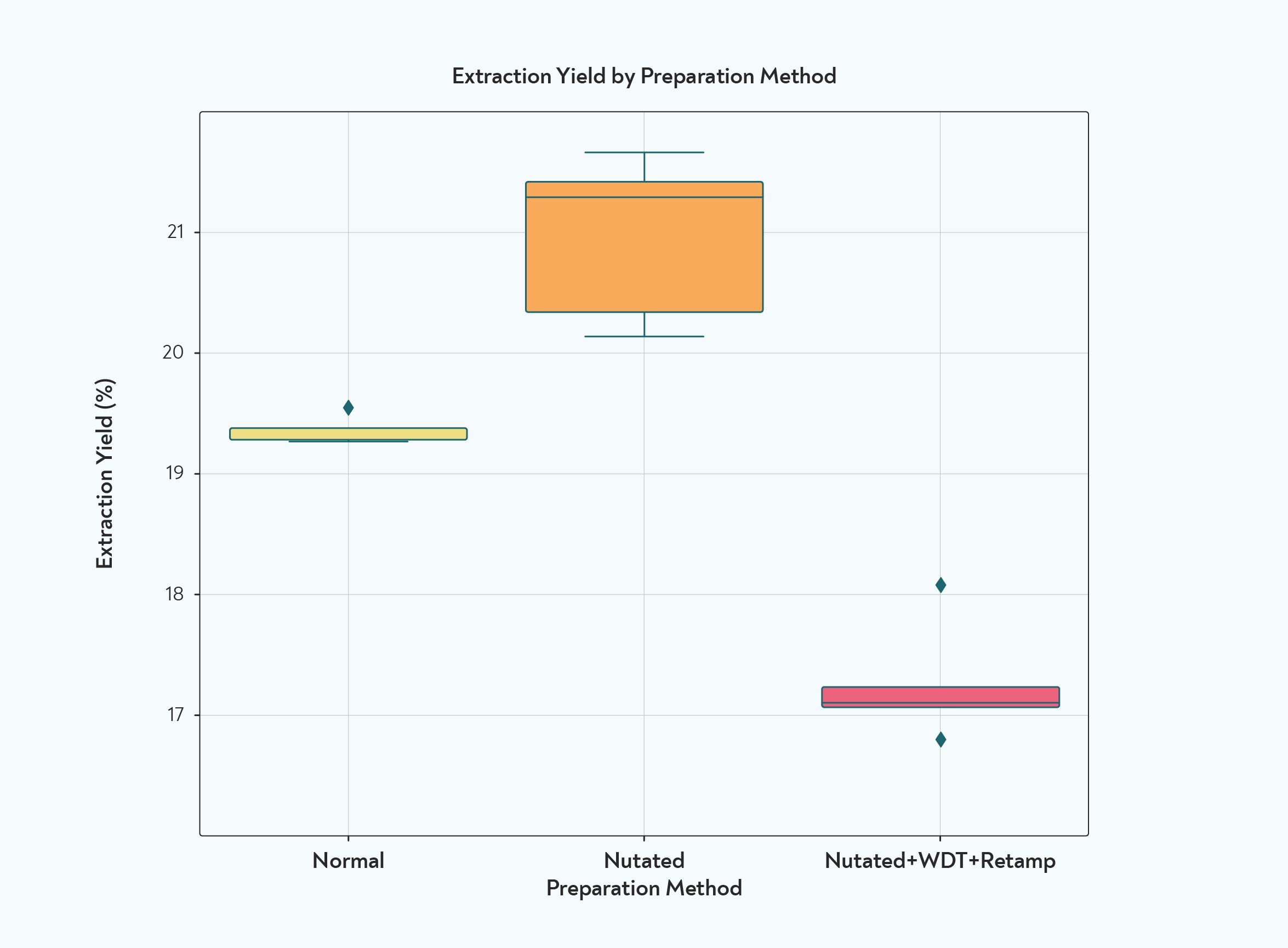

Here’s what showed up: This boxplot shows the distribution of coarse particles (>355 µm) across all three approaches. Normal grinds; nutated grinds on the same grind setting as the normal grinds; and finally nutated grinds on a coarser grind setting that produced the same shot time as the normal grinds — i.e. a 30 second shot.

Here’s what showed up: This boxplot shows the distribution of coarse particles (>355 µm) across all three approaches. Normal grinds; nutated grinds on the same grind setting as the normal grinds; and finally nutated grinds on a coarser grind setting that produced the same shot time as the normal grinds — i.e. a 30 second shot.

Nutation consistently reduced the proportion of coarse particles, suggesting partial breakdown of larger particles. It’s also possible that some larger particles are actually not solid particles at all but are in fact an agglomeration of fines that have clumped together and so nutation could be seeing less boulders in the mix because the ‘micro agglomerations’ are broken up. Coarsening the grind after nutation partly restored the proportion of coarse particles — no surprise there.

The Final Part

The next natural step in this line of argument was to find out what happens if you make espresso with heavily nutated coffee which you then break back up into loose grinds before tamping it again. “Why do that?” you ask. Nutation certainly causes densification of the whole puck, but does it densify individual grinds, or change the size and shape of grinds in a way that benefits extraction efficiency? To find that out, after nutation, we need to break the puck (and any agglomeration that nutation causes) back into nice loose particles with no clumps. So the plan emerged. Grind > Nutation > then WDT > then tamp again. Sounds like hard work, but we had to find out if this approach might not just be the dream boat to puck heaven. Here are the results:

A box plot showing extraction yields for three different puck prep techniques.

A box plot showing extraction yields for three different puck prep techniques.

Left: Normal prep – no nutation, just a standard tamp.

Middle: Nutated prep – where we applied a nutating motion during tamping.

Right: Nutated>WDT>tamp – nutated, then stirred with a WDT comb, re-tamped, and extracted.

Looking at this data, it certainly doesn’t look like the nutated>WDT>tamp approach is a fast track to puck heaven. Our goal was to see how each method influenced extraction yield (EY), TDS, and overall shot consistency.

The nutated shots came out on top in terms of extraction. They pushed the average EY up from 19.35% to 20.97% – a solid 1.6% boost, which is a pretty big deal in espresso — likely due to higher puck density or more uniform resistance during extraction.

But it wasn’t all upside for nutation. Nutation also brought in more variability — the standard deviation for EY jumped from just 0.12 for the normal method up to 0.68. So while the shots were stronger, they were also less predictable.

Nutation>WDT>Tamp method looked promising on paper — maybe a way to get the best of both worlds? In reality, it backfired. These shots had the lowest EY by miles (17.26%) with the most inconsistency in shot time. It seems the WDT just introduced too much chaos into the puck structure.

Does This Data Imply Particle-Level Densification?

When a particle is densified, the open-cells on its surface become internally filled with fines or collapsed by pressure.

This is harder to measure and prove because it requires microscopy, porosimetry, or x-ray CT scanning to confirm. (We’re actually in discussions with Dr Anja Rahn about ways to look into that at the moment). Particle densification involves the following:

- Fines migrating into the interior pores of larger grinds

- Collapse or plastic deformation of cell walls in coarse particles

- Possibly sintering (a process where particles fuse together at raised temperatures and/or pressure from grinding or nutation..

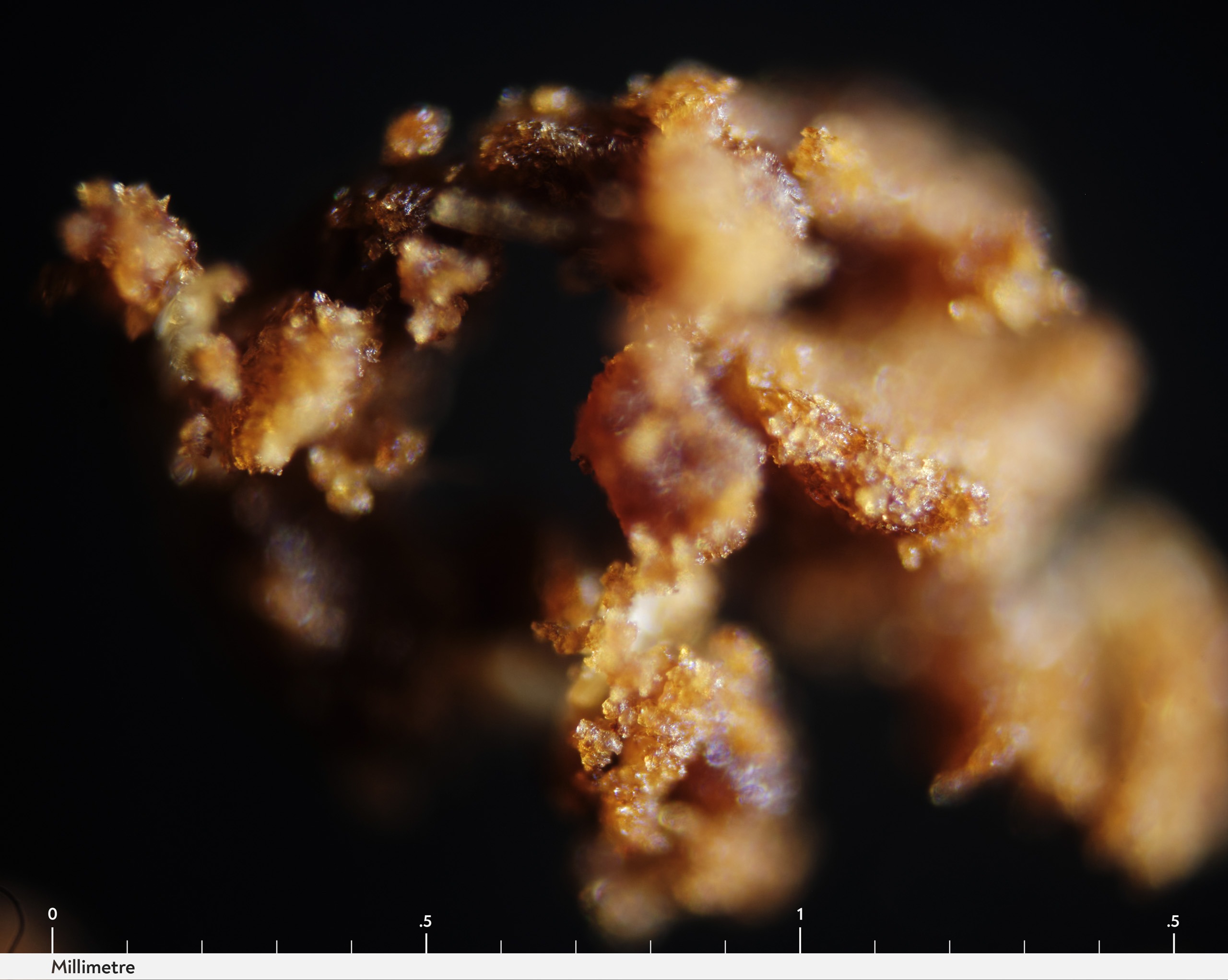

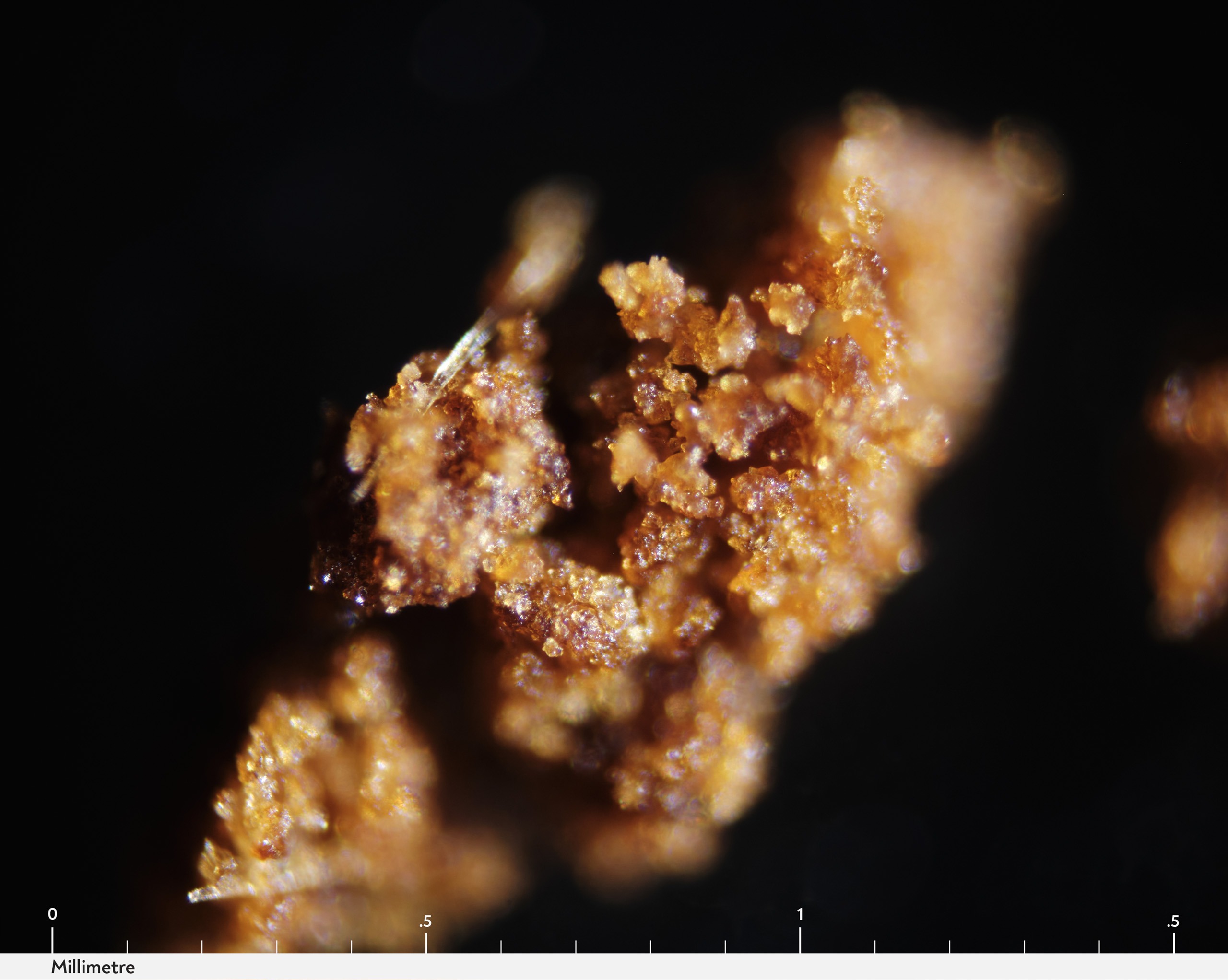

If you crack out an ordinary microscope and compare boulders found in ordinary grinds compared to boulders collected from nutated grinds, you can definitely catch some helpful clues as to what’s going on. Take a look at the microscope images and videos below.

Microscope images at 10x magnification. Normal grinds boulder (left), nutation grinds boulder (right)

Microscope video footage (4x magnification) of the cross section of a tamped puck.

Microscope video footage (4x magnification) of the cross section of a nutated puck.

What’s Next? Nutation Mutation the Sequel

There appears to be fewer voids in the nutated puck but it’s clear that 3D imaging is needed to get a satisfactory answer to this.

First you’re thinking, are these crumbs of chocolate brownie? Then you notice that in both cases, there’s what appears to be agglomeration going on with both the nutated and non nutated grinds. Especially when compared to grinds produced on a much coarser setting. We’ve decided this evidence is at least sufficient to look into this topic further after commissioning some proper SEM images. Once they come back, and a complete particle size analysis, we’ll report back with Nutation Mutation the sequel.

To the boundaries of coffee …