Welcome to half three of my La Minita travelogue – In the event you missed the primary or second a part of my journey, you’ll be able to both start with me in San Jose or be part of me on the farm on the visitor home, or simply dive proper in right here on the mill.

Need a tremendous espresso from La Minita? Store La Minita Melico Geisha.

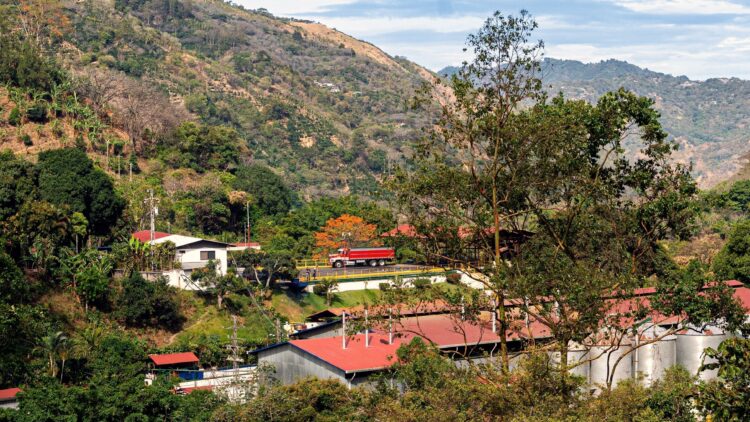

Under the slopes of espresso, on the base of the mountain, lies La Minita’s mill, Beneficio del Rio Tarrazú. What I’m referring to as “the mill” is definitely a moist mill, a dry mill, a roasting and cupping lab, together with workplaces and varied different help buildings – an enormous operation as you’ll be able to see!

We visited the mill within the night and throughout the day, so forgive the combo of lighting circumstances! A number of stations exist for vehicles delivering espresso to unload.

La Minita’s mill additionally serves smaller farms and estates within the surrounding valleys, so vehicles of all sizes come and go all through the day.

Angerias are used for measurement when masses are delivered to the mill, to verify the anticipated amount is delivered, then dropped into holds – as soon as a truck is absolutely unloaded, the processing can start. This processing modifications the espresso from fruit-covered cherry into the dried seeds we name beans.

The espresso’s been delivered, so let’s get to the milling! Espresso arrives on the mill as shortly as potential after selecting. If processing is delayed, the fruit across the seeds will finally spoil or ferment, ruining the espresso.

As soon as the acquired espresso is measured once more and sampled, it drops to a receiving tank crammed with water. A full, extremely detailed description of what occurs to the espresso subsequent is obtainable in La Minita’s mill weblog. I’ll inform you about my expertise of the mill, however the scale, sounds, and sights had been superior and overwhelming – for an knowledgeable description of their world-class mill, please head straight to the supply.

Within the receiving tanks, any low-density “floaters” get channelled away to be processed as decrease high quality espresso. Within the moist mill, the thrum of speeding water and churning machines working away on the espresso dominates any dialog. The espresso must be de-stoned to take away any overseas objects that may have been within the luggage or the vehicles after selecting, then de-pulped to take away the pores and skin.

De-pulping requires just a few machines, to make sure all the espresso stripped of its pores and skin and fruit, as the scale of the cherries varies. The skins get washed away and saved to return to the farm, the place they’ll function pure fertilizer.

If espresso makes it by way of the collection of machines designed for de-pulping with out being de-pulped, it will get sorted away from the very best high quality beans into what are known as “seconds” and “thirds” – this espresso’s nonetheless nice, we received to style it on the cupping desk – however is of course decrease high quality than the perfect espresso of “firsts.”

After de-pulping is full, the espresso will get washed by way of one other channel to the fermentation tanks. These giant holding tanks lie between the receiving space and the dry mill.

Right here, the espresso begins to ferment below managed circumstances, naturally breaking down the sugars that maintain the remaining interior fruit, often known as endocarp or mucilage, onto the seeds. The period of time it rests varies, and is set by the mill supervisor’s examination and judgement of every tank.

As soon as the espresso is prepared, it is washed once more in chilly water, which stops the breakdown of sugars and washes the loosened mucilage away. This washing occurs in an inclined channel with gates at totally different places alongside the incline. This design types the espresso by gravity, because the lightest beans of decrease high quality journey shortly and the denser, extra flavor-packed beans transfer slowly down the channel.

Pura Vida

In a tremendous show of the Costa Rican ethic of caring for his or her biosphere, all the wastewater for these processes is cleaned and returned to a correct ph in a hydro-electric powered water therapy plant. That is extraordinarily uncommon globally – acidic, untreated water is often dumped downstream of farms after milling – and was an enormous reminder of La Minita’s willingness to spend money on the care of their neighbors and the encompassing lands, not simply of their farm. On the farm we noticed areas left uncultivated and wild, take care of and safety of bees, native planting, however this therapy plant is a shining instance of La Minita’s dedication to preserving the atmosphere.

Time to Dry

As espresso leaves the moist mill, it’s time to dry the espresso to the right moisture degree for hulling and transport – and right here, we noticed La Minita use a wide range of strategies.

Conventional patio drying was on show, the place beans are unfold on a concrete patio and repeatedly raked to dry evenly within the solar.

We noticed raised beds all through the mill, designed for drying particular, small numerous espresso, in a conventional African method.

Lastly, many of the espresso processed on the mill travels by way of large, low temp, rotating dryers, powered by state-of-the-art, parchment burning furnaces.

Parchment is the innermost layer of pores and skin that wraps across the seeds, and the espresso is pulled from these huge rotating dryer drums when the parchment feels prepared for removing.

After drying, the espresso enters a interval of reposa, or relaxation – it rests for no less than 20 days. For giant tons, this takes place in huge silos. After this era of relaxation, it’s time for the dry mill to swing into motion – the espresso is hulled to take away the parchment and silver pores and skin, then sorted.

La Minita makes use of as many strategies as potential and says they’re all the time searching for extra methods to type for high quality – we noticed density beds that vibrate (winnowers) to type the beans, measurement screeners tailored to work for espresso, and air density sorters.

Moisture readings are taken from samples all through the method.

The ultimate step is probably probably the most conventional, but in addition demonstrates La Minita’s respect and dedication to producing world class espresso.

A group of ladies sit at hand cleansing tables, inspecting espresso for discoloration, injury, and defects that weren’t detected by all the machines that preceded them.

The method is so meticulous that the highest sorters sometimes prime out at 50 kilos per day.

The mill, nestled beside the convergence of the Tarrazú and the Candelaria rivers, actually does stand as a last testomony to the property’s dedication to high quality and shut care for his or her folks, land, neighbors, and naturally, their espresso.

All the processes, sorting, and work, winnows away decrease high quality beans till solely the perfect stay.

La Minita estimates that of each 100 kilos of inexperienced that arrives on the mill, solely 23 kilos of espresso leaves bearing the title La Minita – the remaining is graded, then offered below lesser marks.

On the Cupping Desk

As a espresso roaster in america of America, it’s not crucial to journey the globe in quest of espresso, it isn’t essential to witness the care and work that go into each bag of espresso we receive- importers are all the time joyful to ship samples to us. There are lots of causes, nonetheless, that it’s extremely helpful to go to estates, farms, and mills in coffee-producing international locations.

The primary may be apparent – should you’re at a farm throughout harvest, tasting pattern roasts the day they turn out to be obtainable, you usually have the within observe on negotiating to purchase it, merely since you received to style the espresso earlier than anybody else.

The following cause may be much less apparent – after we make a dedication to relationship coffees, it’s not primarily based on pamphlets we’re receiving. As a substitute, we’ve visited the farm, we’ve seen their dedication to high quality, to their atmosphere, to their farmers, to all of our shared values, and we’re dedicated to purchasing not simply their finest coffees, however sufficient of a wide range of their coffees, repeatedly, harvest after harvest, in order that they know they will depend upon us over time, similar to we rely on them.

Standing at an open air cupping desk beside the roasting lab, surrounded by a panel of consultants from La Minita- roasters, mill employees, high quality management managers, the farm supervisor, the visitor home supervisor, all our hosts – it was clear that every little thing La Minita prides itself on is embodied of their folks. Their work, dedication, planning, improvisation, care, and pleasure had been all on show across the desk.

They created three cuppings for us, letting us style a variety of sorts, farms, processes, drying strategies, all three high quality grades, and extra. The whole lot they achieve this properly was overtly shared – with time for questions, debate, pleasure, and pura vida .

And as in all of our visits to La Minita, it was obvious at that desk why our green-buyer, Bob Benck, has returned, decade after decade, to the folks and occasional of La Minita, from his desk at Dancing Goats.

We’re proud to supply Costa Rica La Minita to you this 12 months and we’re proud to rely it as a relationship espresso that we are able to now share with an excellent bigger group of espresso lovers.

I’m additionally thrilled that we’ve chosen to deliver you a uncommon, prized, and extremely scrumptious Geisha selection by the use of La Minita: Finca El Melico. Thanks for studying about my journey, sharing a number of the lovely sights of Costa Rica with me, and I hope you’re keen on the espresso from La Minita as a lot as I do. Till subsequent time, pura vida mae! -Aaron