Hi there All,

I do know it’s been troublesome to stay affected person whereas we type all of this out however we might relatively get as many anomalies sorted after the primary spherical of shipments earlier than persevering with to ship extra models. The excellent news is that issues are wanting promising from right here.

Bumpy Roads

Whereas our new facet panels have a a lot cleaner match than the originals, they’d a decent squeeze between the back and front covers. We’ve had some Argos house owners contact us a few nook that will get pushed out from flush once in a while throughout common use. After re-confirming with our drawings, our provider sadly didn’t account for the coating/end utilized on the facet panels and the additional 1mm thickness added was sufficient to trigger some panels to have a nook pushed out underneath compression.

We’ve labored with the provider to get new panels made to the right spec. Within the meantime, we’re utilizing a belt sander and 3d printed jig to take away the additional 1mm off our current facet panels and refinishing them in order that we are able to ship out replacements to anybody with the problem freed from cost and maintain constructing models. This can even enhance among the meeting delays and QC struggles we had with match and end over the previous few weeks.

In hindsight this could have been the very first thing that we checked but it surely’s straightforward to say that after the very fact once we aren’t scrambling to type out our processes on the fly.

Steam Valve Leaking

We’ve observed some machines that drip water out of the steam wand regardless of being absolutely closed. Our steam wand is a personalized needle valve containing a quite simple needle design that works 95% of the time however isn’t as strong as we want. There are 2 points with it. The primary is that we had the needle/ plunger hardened. That is nice for longevity of the needle however sadly extra inclined to gentle floor corrosion over time. The second concern is that almost all espresso machine steam valves are both constructed from brass which is a a lot softer steel that may permit the needle to evolve and seat inside the orifice higher or they use a teflon seal.

We experimented with completely different teflon gasket and seal sizes choices that we hoped might be added into our current valve to enhance sealing however all of them had points with the steam pushing them misplaced and blocking the circulation path barely. We mentioned this with our provider and have give you a design that comes with an o-ring into the angled portion of the needle which ought to permit correct sealing with out the o-ring shifting inside the valve physique. This will likely be one thing that may be simply changed in time. Since we received’t want to fret concerning the needle carrying out, we’ve additionally opted to change the plunger again to a non-hardened stainless-steel. A batch of 10 samples is predicted to be accomplished tomorrow and may ship out the next day. If these work as deliberate we are going to do a manufacturing run and swap these needle/plungers into our current valves in addition to ship them out to any folks that have already got a machine with directions on tips on how to swap.

This is not going to be a blocker for transport machines out because it’s simply replaceable with a single wrench and an allen key.

PCB Spacers

We’ve had some house owners report points with the machine not turning on or tripping gfci shops. With the assistance of some extraordinarily affected person Argos house owners we have been in a position to diagnose the problem which seemed to be a mixture of placement tolerances once we taped the PCB mounts with electrically resistive tape in addition to transport hundreds inflicting the PCBs to barely rattle. This rattling mixed with tape that was positioned barely too low would permit a single solder on the again of the board to quick out. We’ve sourced a rubber spacer to be put in in an unused screw gap of the PCB which stands it off sufficient for there to be no manner for the PCB to contact the steel plate it is mounted to.

Low fluid stage sensor

We simply had one Argos proprietor report the low fluid stage warning gentle approaching even after refilling the water tank. After taking a look at photos of the sensor, we discovered that the steel probe had slid down the sleeve it sits in. This led to an air pocket above the probe which reduce off conductivity from the sensor by means of the water. These sensors come preassembled, however shifting ahead we’re going to make sure all sensors are tightened after putting in them.

Transport Updates

The facet panel changes, tightening low fluid stage sensors, and PCB rubber spacer have now all been added to our constructed up stock. We are going to do one other spherical of QC then start transport all of our constructed up inventory out whereas persevering with to construct extra machines. I do know it’s been troublesome to stay affected person whereas we type all of this out however we might relatively get as many anomalies sorted after the primary spherical of shipments earlier than persevering with to ship extra models.

Movies

Listed below are the movies we promised from the final e-mail replace!

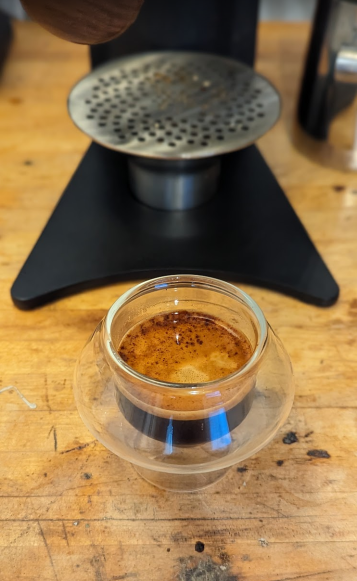

This new video was simply posted by Brian Quan from a current San Francisco espresso meetup displaying the Vectis and Argos facet by facet! We’ve all been ready for it so that is thrilling to see the variations in dimension and pull approach. We should remember that neither of the pictures pulled have been dialed in very effectively with grind dimension and this Argos has a 6 bar spring whereas the Vectis makes use of an 8 bar which is able to make the type of shot pulled utterly completely different as talked about within the video. Regardless, it’s enjoyable to look at and see them each out within the wild.