Hey Everybody,

Abstract:

Over the previous six weeks, we’ve confronted some sudden challenges with a small batch of components arriving out of spec, which affected our achievement price. Whereas we had efficiently labored with these suppliers earlier than, this batch offered some unanticipated points each visually and functionally, however we’ve been totally dedicated to resolving them.

To make sure the very best high quality requirements transferring ahead, we have taken proactive steps, together with a number of journeys to China to satisfy with suppliers in individual and higher perceive the basis trigger. Because of this, we have already carried out the mandatory corrections to enhance the components’ high quality.

We’re excited to report that after the newly improved components arrive at our store, our staff will be capable of function at full capability. As soon as at full pace, we’ll instantly look into increasing our staff by hiring extra technicians to additional speed up achievement and enhance supply instances.

We tremendously recognize your endurance and understanding, and we’re assured that these steps will assist us present everybody with a good higher expertise going ahead.

NOTE: As of this afternoon, a cargo of powdercoated components has simply arrived and constructing has formally commenced!!!

Provider Visits:

Whereas in between batches 1 and a couple of, William and I made a decision to make a journey out to China on the finish of October to take a position a while in assembly our massive suppliers, reviewing some design modifications and points we had with new samples. Since we’re not precisely a big buyer for a few of these corporations, these visits are an necessary half in constructing a robust relationship and making certain prime quality and constant components.

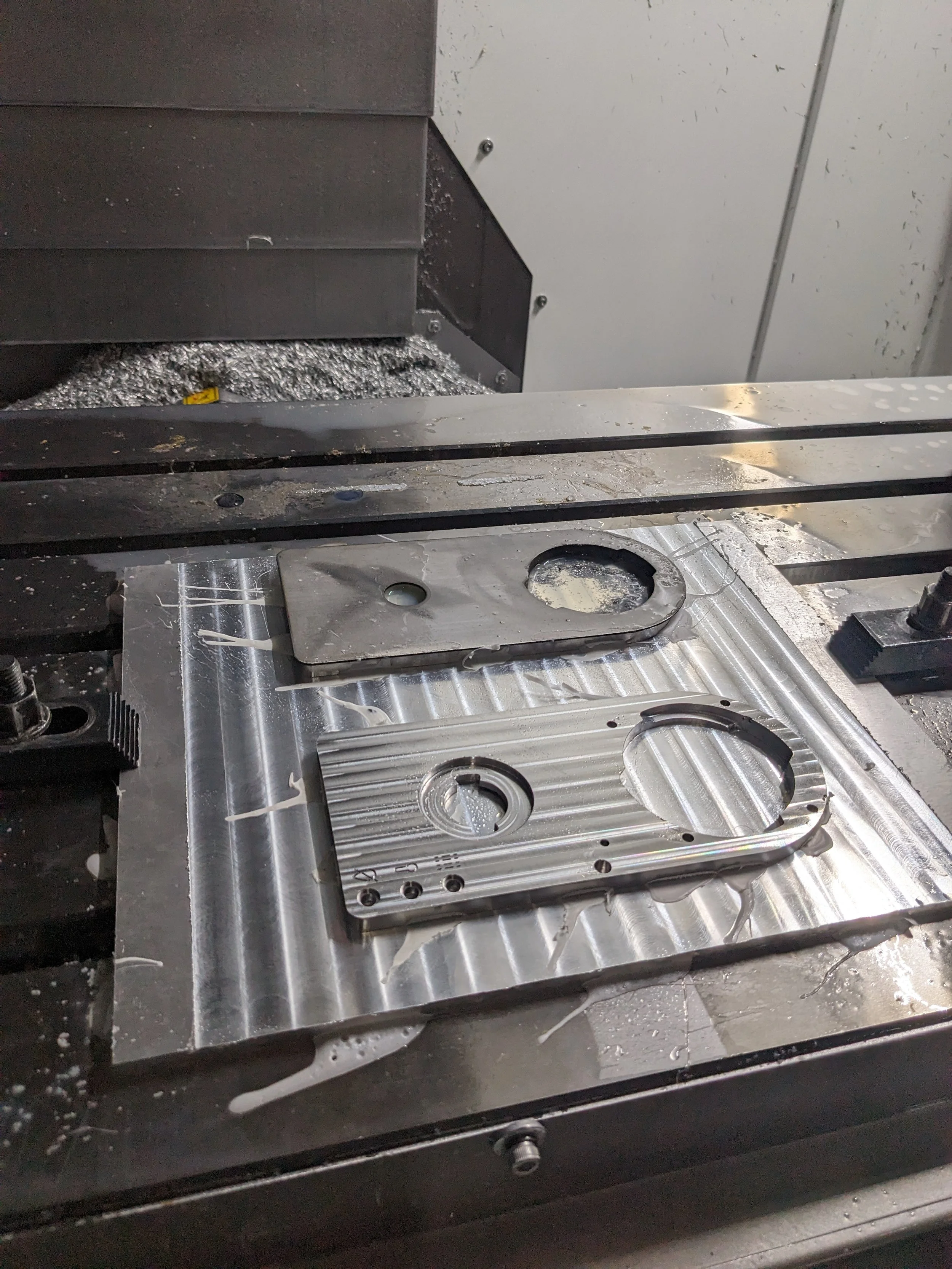

On prime of assembly our representatives and their engineers in individual, we weren’t solely capable of have actual time manufacturing critiques, but additionally capable of see how components like our boilers are actually welded and hydrostatically stress checked by the provider in addition to how our sheet metallic components are laser lower, get their brushed floor end, bent, then lastly inspected. All of this info is extraordinarily precious for understanding manufacturing constraints to enhance the design in future iterations.

New Elements:

We acquired 45 units of stainless-steel components by air from an current provider and effectively, whaddya know, manufacturing simply doesn’t get any simpler. Whereas the machining high quality had considerably improved from the unique samples this fall, the brushed floor end was nonetheless less than par in comparison with our unique Batch 1 items. The end was far too coarse and left some unappealing gashes and perpendicular rippled results on the components. This isn’t one thing we will comfortably ship to our prospects. We’ve spent the previous 3 weeks working with the provider and digging by way of our documentation to see what strategies they used up to now vs what was just lately achieved.

It’s been 2 years since we ordered our unique components and this firm’s employees, location, and instruments have all modified which has led to the inconsistency. Sadly, these discrepancies weren’t seen on the brand new samples that we had simply permitted. The provider has been engaged on correcting this end with new processes which we’ve simply permitted and are happy with the outcomes after seeing a a lot bigger pattern measurement.

Some lingering points stay from Batch 1. Certainly one of our extra annoying issues has been with our boiler stress gauges. These are a barely personalized gauge that use lead free solder to keep away from any leeching into the boiler. As many individuals know, we had points with gauges fogging up in our first batch which affected ~10% of our inventory. Whereas every gauge goes by way of 2 rounds of QC testing on the machine earlier than transport, generally the inner fogging would current itself after being shipped. Whereas it’s not troublesome to swap this half out, it’s nonetheless very inconvenient as there shouldn’t be any inside leaks after they’re produced.

The provider was knowledgeable and we despatched again 20 unhealthy gauges for them to disassemble, diagnose, and resolve on the following order. Sadly, after receiving the brand new order of gauges 2 weeks in the past, even MORE gauges are fogging up.

The second lingering difficulty has been inconsistencies within the coiling of our heating components. This will result in difficulties with putting in in our tightly packed boiler in addition to struggles with getting them to appropriately seal. I’ve designed a quite simple 3D printable go/ no-go gauge to simulate the underside half of the boiler with our fluid stage and thermocouple probes protruding. The objective right here is for the provider to examine every heating factor after coiling to make sure fitment with out points earlier than transport to us. It will enable them to make any needed changes on their finish and save us the complications throughout set up.

China Half 2:

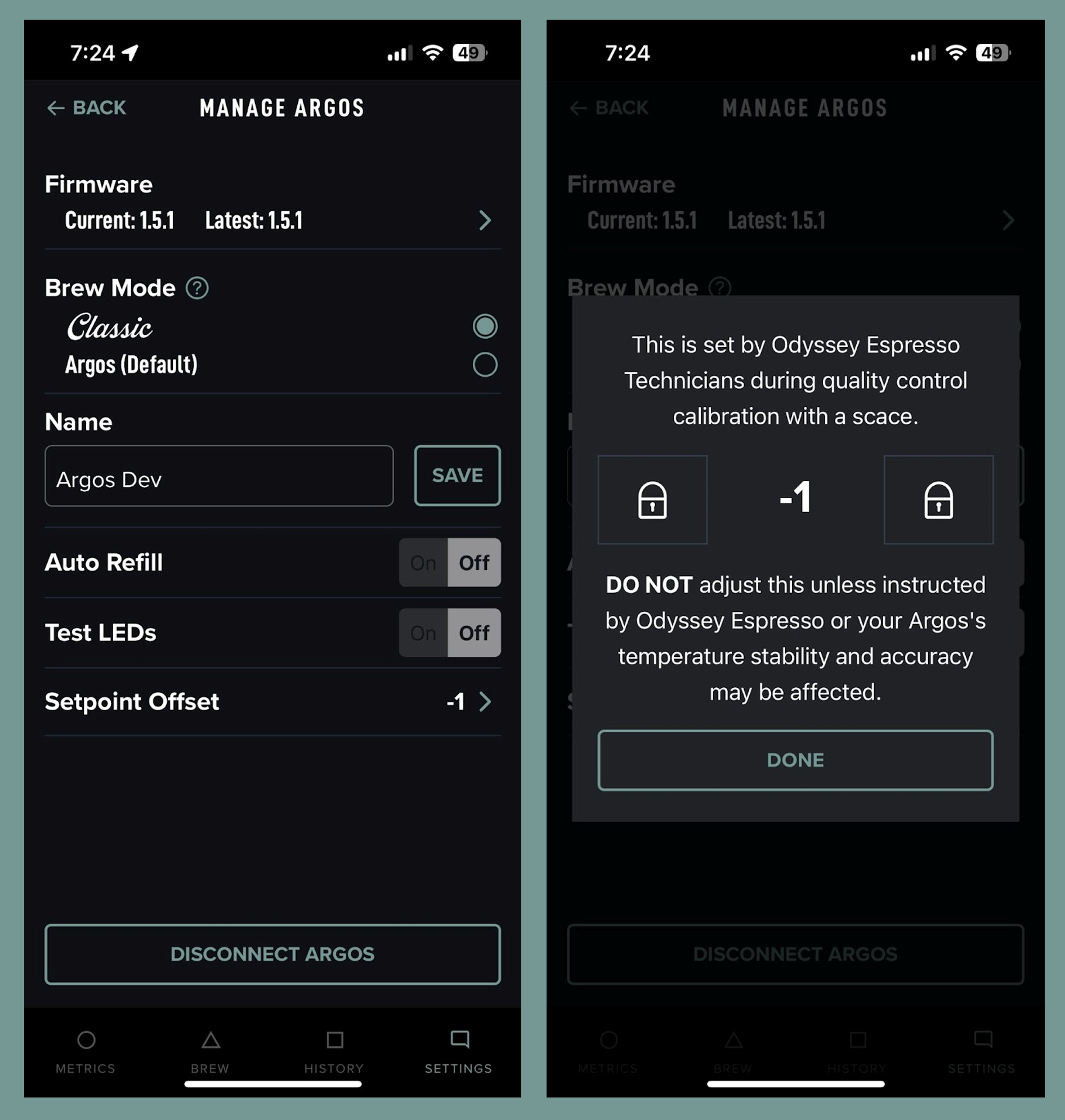

I by no means thought to go to these suppliers on the unique journey final month however as a result of these latest points and our recurring manufacturing schedules, I made a decision to make a fast final minute journey again out to China. I’ve simply completed working with our machined plate provider to make sure we get the suitable end and ensuring their techs are accurately educated on the brand new procedures. This store ground time allowed me to essentially perceive the place a few of our points had been coming from, approve present procedures in actual time, evaluate powdercoating, inspection, and packaging all in actual time. I’ve obtained a number of motion objects for issues to regulate on the drawings and procedural documentation earlier than we order extra components in every week however I’m assured that this time funding will repay transferring ahead with extra constant outcomes.

I additionally introduced a number of the new unhealthy gauges to disassemble and diagnose on website with our gauge provider. This gave me necessary perception into their meeting and testing course of. General the method ought to be fairly strong however I feel there’s just a few small modifications we will make to cut back our points. A possible trigger for the fogging could also be residual moisture inside the duvet from meeting which collects on the higher lens when heated. One other chance is an improperly combined adhesive having a response to the excessive temperatures of the brass base of the gauge that it’s bonded to. We’re at the moment testing a number of of those potentialities with the provider to slender down and mitigate this difficulty sooner or later.

With new heating components being coiled I used to be capable of go on website to study in regards to the course of and be sure that they perceive our issues and struggles with the gauge inconsistencies. Because the ultimate bends and factor tolerances are all adjusted by hand after a machine does the coiling, the brand new 3D printed fixtures enable every factor to undergo a take a look at match process the place I used to be capable of affirm good fitment which can considerably scale back boiler meeting time.

Whereas it’s not essentially the most handy to fly all the way in which again out to China, I’m at all times excited to find out about how extra of our components are produced in addition to assure a well timed decision to our lingering points. These sudden points do delay us a bit, however I feel that the extra up entrance time funding will repay in the long term and never delay our total batch 3 supply instances which have a 1 month manufacturing buffer for Chinese language New 12 months.

I had the chance to satisfy up with an acquaintance from School who additionally does product design and owns a machine store in China. Since he too has to outsource a few of his personal components to different Chinese language producers, he assured me that that is all part of the method, particularly when going to pre-production to 500+ manufacturing scale. Primarily, I’m doing the position of a Provider High quality Engineer (SQE) which isn’t one thing I used to be ever accustomed to in my prototyping background. Whereas this position might be outsourced, I discover that I do benefit from the on website downside fixing and constructing interpersonal connections with our key suppliers.

Store Progress:

We spent 1 week buying instruments and testing strategies to recreate the unique floor end ourselves within the store however this proved to be way more troublesome than anticipated. Now that I’ve understood the brand new course of on website, I’ll try and discover a comparable machine within the US but when this doesn’t pan out, we’ll ship the components again to be fastened by the provider with new Stainless plates being despatched out by air this week.

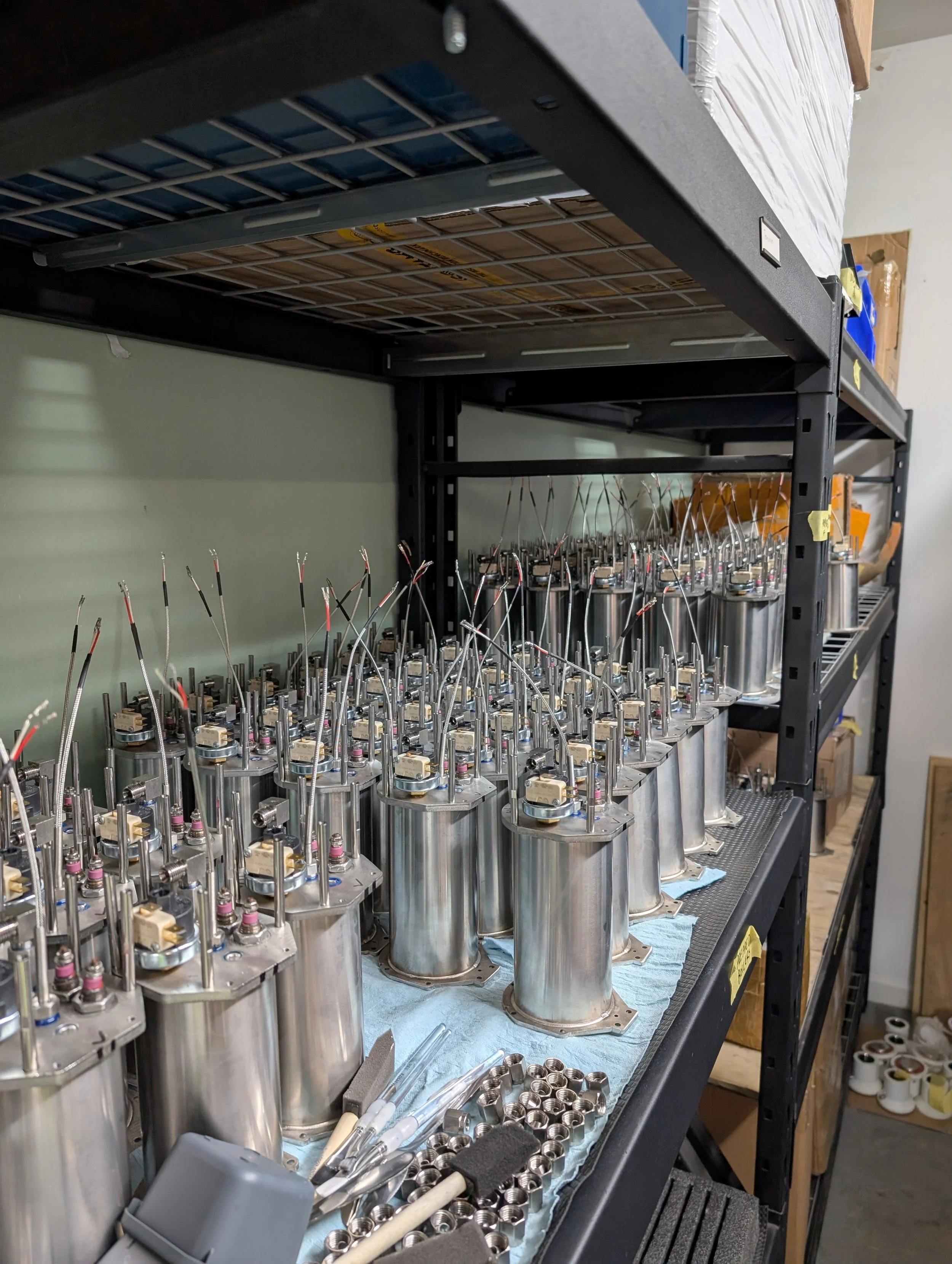

Whereas it’s unlucky that we weren’t ready to make use of these stainless items instantly, we’ve nonetheless been capable of construct up over 100 units of sub assemblies in preparation for the powder coated components to reach this week then corrected stainless components quickly after.

New Piston Linkages are in and transport instantly. These will formally roll out with serial no 600. The one important benefit of this half is increased yield within the direct configuration making the yield nearer to 50g.

Our new piston gauge brackets have resolved the unique alignment difficulty and can make set up a lot simpler than earlier than.

Beginning mid January, we plan to increase into the store adjoining to ours. Our objective could be to open up the wall between the two models permitting us to maneuver our mini “machine store” and extra storage to the opposite facet whereas making extra space for meeting and transport. It will set us up effectively for continued development within the new yr as we proceed to ramp up meeting and fulfill orders.

Software program

The newest firmware model on the time of this weblog is 1.5.1 which features a minor bug repair to revert the temp tolerance for getting into sleep mode to be what it was in an earlier launch. We had made this too tight and because of this some machines didn’t enter sleep mode after ~10 minutes of being on the set temp. Please replace to this newest model when you’ll be able to.

We’re nonetheless working by way of Acaia scale integration points and have been involved with Acaia representatives for assist. Sorry for the continued inconveniences!

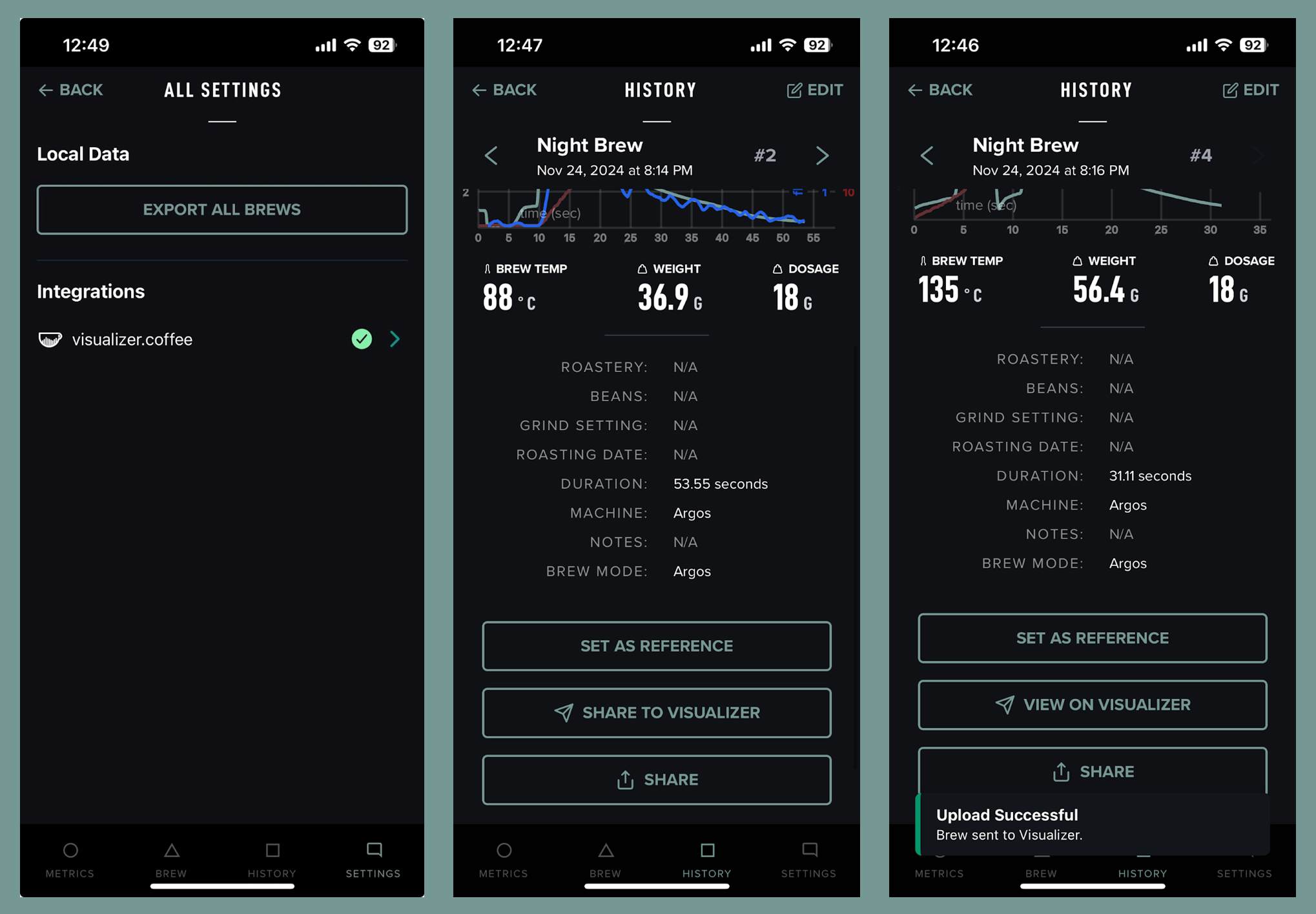

Steve, our half time app developer, has been working laborious on a https://visualizer.espresso/ integration which we’re excited to announce has been launched within the app! Go to settings tab and click on the gear icon on the highest proper and choose visualizer.espresso and observe the prompts to get linked. Then you definitely’ll have a brand new “share to visualizer” button for every brew and after it has been uploaded you’ll be able to click on “view on visualizer” and it’ll open up the brew in your browser. We’re additionally engaged on our personal platform that enables for person accounts and backing up/sharing pictures.

Moreover we wished to remind everybody that the setpoint offset is about by our technicians throughout qc with a Scace to make sure correct and constant brew temps primarily based on the temp set by the dial and it’s particular to your machine. Don’t change the setpoint offset your self as a result of it’s possible you’ll have an effect on accuracy and consistency of the temperature stability of the Argos. We’ve made an replace to the app to make it more durable to by chance change in addition to together with a discover.

We actually recognize everybody’s help as you all go on this journey with us whereas we create these superior little machines!

Sincerely,

Ross & William