Whats up All,

We’re lastly transport once more!

Delivery Updates

We’ve shipped 22 items and are beginning to get right into a groove! 32 extra machines are already constructed and sitting on the shelf. Just a few items are being examined and checked for high quality every day and shipped out as they’re accomplished. We’ve spent the previous two weeks updating a whole lot of these beforehand assembled items to incorporate our latest fixes for points that had been popping up after transport. All shipped machines with these recognized points have additionally been mounted and despatched again to prospects. Up to now, our updates appear to have resolved the prior issues that we had been seeing which is nice for transferring ahead.

LED Endurance Testing

We’ve began to do some endurance testing on LEDS earlier than putting in to confirm that they’re functioning correctly. The testing includes hooking ~ 10 LEDs as much as a breadboard with a 9V battery and leaving them on for one hour earlier than set up. Sometimes one out of each 20 LEDs will burn out throughout this take a look at which saves us from discovering this out throughout QC and requiring extra disassembly.

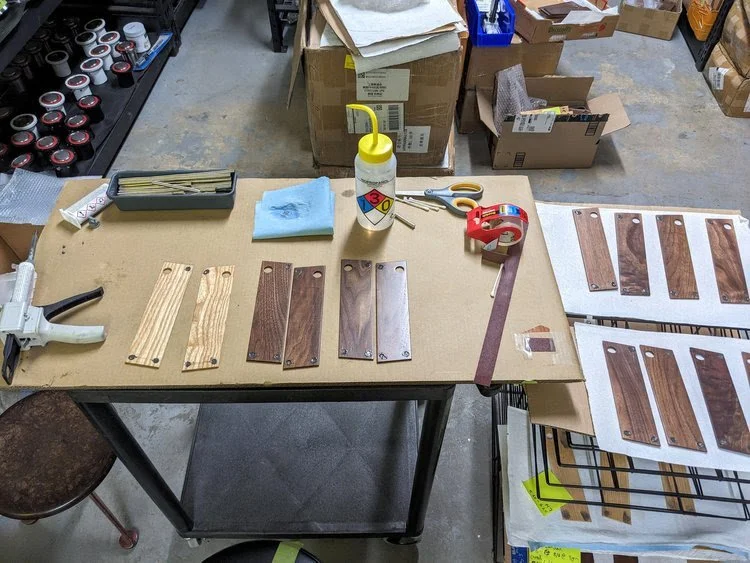

Advantageous Tuning Panel Fitment

We obtained samples for the up to date facet panels that meet our specs after the coating has been utilized. These match precisely as we want so we moved ahead with a brand new manufacturing batch. Within the meantime we’ll be utilizing the entire pattern panels and manually sanding down and refinishing the outdated panels to the right spec till the brand new panels are obtained.

New Steam Valve Needle

After testing a number of completely different steam valve needle prototypes, we’ve discovered a winner and have ordered a manufacturing spherical of the elements. We had been in a position to make use of the remaining samples in a number of manufacturing machines however the full batch gained’t be accomplished and shipped till subsequent week. All prospects which have already obtained machines can be despatched the brand new elements with set up directions.

Air Bleed Valve Enchancment

Based mostly on buyer suggestions, the steepest studying curve with the Argos is bleeding the entire air out when pulling the lever. We’re engaged on bettering the person expertise by simplifying the air bleed course of to make it much less reliant on person approach. After preliminary testing, a small orifice that restricts the stream of water coming into the grouphead seems to behave in the identical method as holding the piston within the appropriate place whereas bleeding the air. There’s an ideal house between the threads of the fill tube push to attach becoming and the grouphead the place this small orifice may be put in to limit stream simply earlier than getting into the group. We’ll take a look at out completely different diameters and if we give you a design that considerably improves the group fill and air bleed course of, we’ll transfer ahead with manufacturing these elements and phasing them in on all builds whereas sending out to present prospects simply the identical because the steam valve needles.

Remaining Components Shipments

We’ve obtained all our elements and packaging supplies by sea. We initially despatched half by air and half by sea so all manufacturing elements are in hand.

White Grouphead

Sadly we observed that a number of the white groupheads had been forming floor corrosion upon arrival. Now we have 9 usable items however the provider was in a position to return into their information and located that the one that did the ending course of on simply the white groupheads did a step out of order which led to this. They are going to be remade and despatched over by air. This shouldn’t trigger any delay for the white machines as the nice ones can be used on any early orders.

CE Certification

I’ve had a number of extra calls with the certifying lab this week to go over excellent gadgets. Considered one of many tedious elements to this course of is getting materials datasheets from each provider for each half on the machine to ensure that its elemental make-up complies with RoHS and REACH necessities. We had 3 elements that had incorrect documentation and we had been in a position to get that resolved final night time. With this being the final piece of the certification puzzle we’re assured in our compliance and can begin transport all abroad orders as they present up within the queue.

Sincerely,

Ross & William