Hiya All,

I sincerely apologies for the shortage of communication. Many struggles over the previous month however progress remains to be being made! As at all times, there’s excellent news, unhealthy information, and classes discovered. I’ll begin by highlighting the three important points we’ve been operating into.

We’ve been noticing some set up challenges and sealing points for the heating components that we use. The coil has a constructive and adverse aspect for wiring every of which seals with a rubber o-ring. It’s troublesome to manage the parallelism between these two planes which implies that in lots of circumstances, one o-ring will get compressed greater than the opposite which results in inconsistent sealing. I designed a customized teflon gasket which is able to permit for compression variations between the 2 sides with out impacting sealing. We must always have these components in by the top of the month.

The second challenge has been the fill tube that leads from the boiler as much as the grouphead. The producer did no make the bends as tight as wanted which has led to set up challenges for the tubes which might be out of spec. We’re in a position to “cherry decide” the nice tubes and construct with these for now. I’ve designed and despatched a jig for the producer to 3D print and validate all bends for one more batch of tube. We also needs to have these by the top of the month which is able to considerably cut back the time it takes for the ultimate stage of meeting the place the grouphead mounts onto the highest plate.

The third challenge comes from CE compliance. We handed the EMC/EMI portion of compliance testing with the caveat that we add a mains filter to our IEC inlet (the place the plug goes into the machine). Which means we’ve needed to supply a brand new IEC socket that mounts into the again cowl. The nice factor is that this is likely one of the ultimate steps of set up however the unhealthy information is that the IEC sockets which have in-built filters require a gap that may be a few millimeters bigger than our unique design.

The quickest technique to accomplish that’s by way of laser reducing or waterjetting the again panels to enlarge the cutout. I simply received the primary quote for that work this morning and anticipate one other quote by the afternoon each from native retailers. Sadly all retailers are booked 2 weeks out however the precise work ought to solely take every week which suggests these can be accomplished early Could. With it being the final step within the meeting course of we will nonetheless proceed to construct and take a look at machines till we obtain these. I’ve already sourced the filters and can get these ordered this week to have that stock in inventory by the point the covers are full.

The lab is writing up compliance documentation now which technically permits us to start out transport within the US/ Canada. Part 2 of the testing is common security. With the tried and true design of levers I’m hoping for no snags on this portion of the take a look at so long as we have now all the right warning labels within the obligatory places.

I cannot give any particular dates that we’ll begin transport by since that clearly didn’t work nicely for me prior to now however new machines are being construct up every week from the nice components that we have now on had and the meeting course of will solely earlier than extra environment friendly once we obtain the brand new components on the finish of the month. We’re at the moment early Could to have the laser reduce panels again in hand and again on the machine so one which occurs we’ll have one other replace with particulars on product transport out quickly after!

Springs. When testing over the previous few months I used to be discovering that the 8 bar spring was actually solely producing about 7 bar stress. When wanting again into my calculations I noticed that I had truly determined to make use of a 7.75 bar spring which had considerably elevated lifecycles however resulting from typical losses in a mechanical system was solely producing 7.25 bar. I went again to my calculations and dealing with the spring producer to have some pattern 8.5 bar springs made with an anticipated lifespan of over 100,000 cycles.

I didn’t really feel snug promoting an 8 bar spring and delivering a 7 bar spring so I ordered stock of the brand new design which got here in final week. As a present for the persistence, everybody on this first batch of machines will obtain the 7 bar spring that I had initially ordered.

Packaging design goes nicely but in addition had some delays. We switched to a molded pulp insert design earlier this 12 months which extra structurally sound and made packaging all of the elements a lot easier. These samples got here in just a few weeks again and match nice. These items at the moment are in manufacturing and will obtain them early Could.

SCA Expo in Portland this week! William and I might be there with black, white, and stainless manufacturing machines on show at our Sales space 1057! Now that we’re in manufacturing, we’ve entered the Argos into the design competitors for Greatest New Client Preparation and Serving Tools (Electrical) which you’ll be capable of see on show. We may have the brand new Zerno Z1 on show at our sales space and might be pulling pictures at 11am and 2pm every day of the occasion. We are going to solely pull ~10 pictures every session since our small lever isn’t optimum for steady industrial use. In case you’re fascinated with trying out the Argos or the Zerno in use then swing by the sales space to check out some espresso.

If anybody remains to be on the lookout for a cross to the expo we have now just a few free 2 day passes left to provide out so ship an electronic mail and we’ll make that occur!

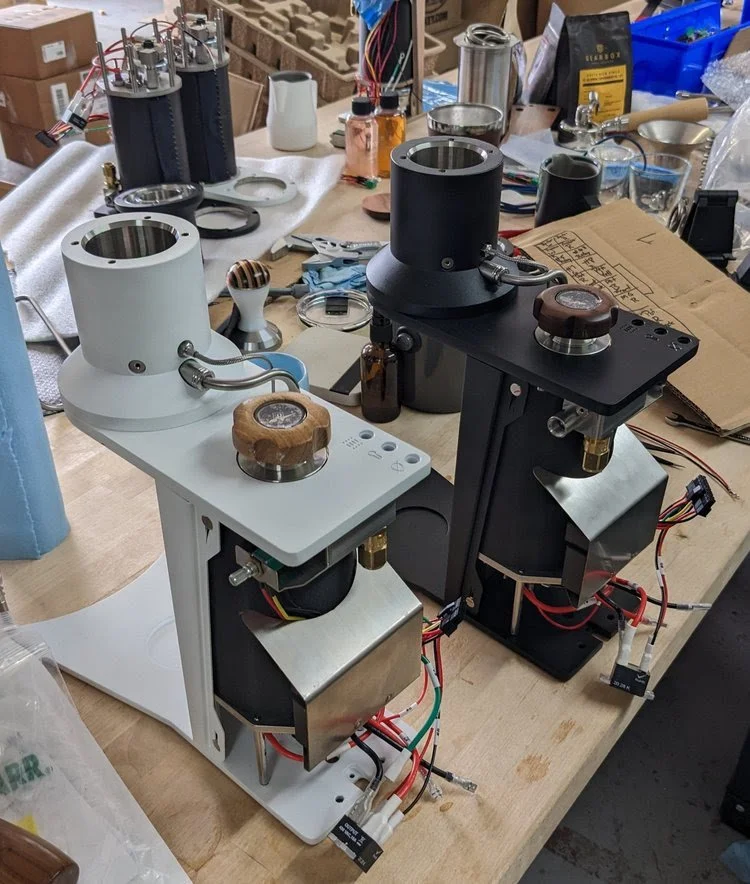

Argos meeting line

First few podercoated machines

All wired up

Molded Pulp packaging insert pattern fitment.

Sincerely,

Ross Ainsworth